Products

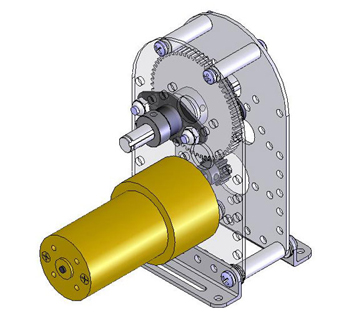

Build a Transmission Module

The Transmission Module is a Stand Alone Engineering or Science Demonstration Project

The Universal transmission module can easily be configured as a Prony Brake as shown in the image.

The prony brake configuration can be used for experiments involving:

The Universal transmission module can easily be configured as a Prony Brake as shown in the image.

The prony brake configuration can be used for experiments involving:

- Current and torque relationships

- Voltage and RPM (speed) relationships

- Motor and drive train efficiency analysis

- Motor and drive system power measurement

This experimental data can be used to analyze and predict:

- Motor and drive system performance for robots, winches, and other mechanical applications.

- Mechanical force, work, and power

Knowledge gained from analyzing the motor and transmission system can be integrated into a variety of applications including:

- Heavy duty mobile platform drive systems

- Robot arms, cranes, winches, and pan or tilt mechanisms capable of 350 – 1500 ounce inches of continuous torque (Depending on the motor and gear combination)

Optional Accessories

- Diode controlled cam operated limit switches with adjustable stopping positions in (2) directions.

- Adjustable length arm assembly.

- Pneumatic gripper/end effector.

- Gear head motor choices:

- 19.7:1 ratio @ 9.55 volt winding

- 65.5:1 @ 12 volt winding

The Transmission Module Teaches S.T.E.M.

Build and use the Pneumatic Test Module to Explore Engineering Principles

The GEARS Transmission Module is designed to be used in mechanical and electromechanical engineering laboratory experiments, activities, and projects.

Industrial Quality ComponentsThe Transmission Module comes standard with a 218.4:1 @ 24 volt winding motor. Other motors are available as options. See optional accessories. All motors have factory specification sheets to facilitate mathematical modeling of motor and gearhead performance.

Frame Construction

- 6061 T-6 x 0.090” aluminum alloy transmission plates with predrilled holes to accommodate multiple gear ratios.

- 3/8” diameter steel axle with precision machined keyway and keys

- Self aligning bronze sleeve bearings rated at 270 lbs axial load.

- T-6 aluminum drive wheel ideally suited for use as a prony brake disc or attachment point for torque arms, pulleys, sprockets, and other experimental components.

Steel Gear Sets

- Steel driven dear: 60T x 24 Pitch x 3/8" face width

- Steel drive dear: 15T x 24 Pitch x 3/8" face width

- Stock ratio - 4:1

This product can be used as a stand alone power transmission device or it can be fitted with limit switches, and/or a 500 cpr quadrature optical encoder. The GEARS Universal Transmission module is an excellent add-on module for both the GEARS-IDS kit projects and the Heavy Metal Chassis platform.

GEARS Supplies Complete Documentation

Illustrated Construction Guide

Sample engineering lab activity lesson